Since 1985

For over 40 years, M&F has evolved from a small Pacific Northwest repair shop into a nationally trusted, engineering-driven manufacturer of complex structures, heavy-duty tooling, and aerospace-grade machinery systems.

Specializing in large and/or technically demanding projects that integrate multiple manufacturing disciplines under tight deadlines, we thrive on the biggest challenges —delivering turnkey solutions and exceptional execution at record speed.

As we mark four decades of craftsmanship and innovation, we continue expanding capabilities, embracing new technologies, and solidifying our role as a preferred partner to next-generation advanced-manufacturing OEMs.

Key Capabilities

Heavy Fabrication & Welding

Large weldments and multi-ton structures are at the core of M&F’s heritage. Our certified welders and fitters build high-strength assemblies from plate, structural shapes, tube, and machined components—with the craftsmanship required for aerospace tooling, heavy-duty machinery, and industrial equipment.

M&F’s welding team is certified across carbon and alloy steels, stainless steels, and aluminum, and experienced in FCAW, GMAW/MIG, GTAW/TIG, and SMAW/STICK processes.

We take great pride in delivering high-quality, high-precision weldments, all produced under documented internal procedures and AWS-qualified welding standards.

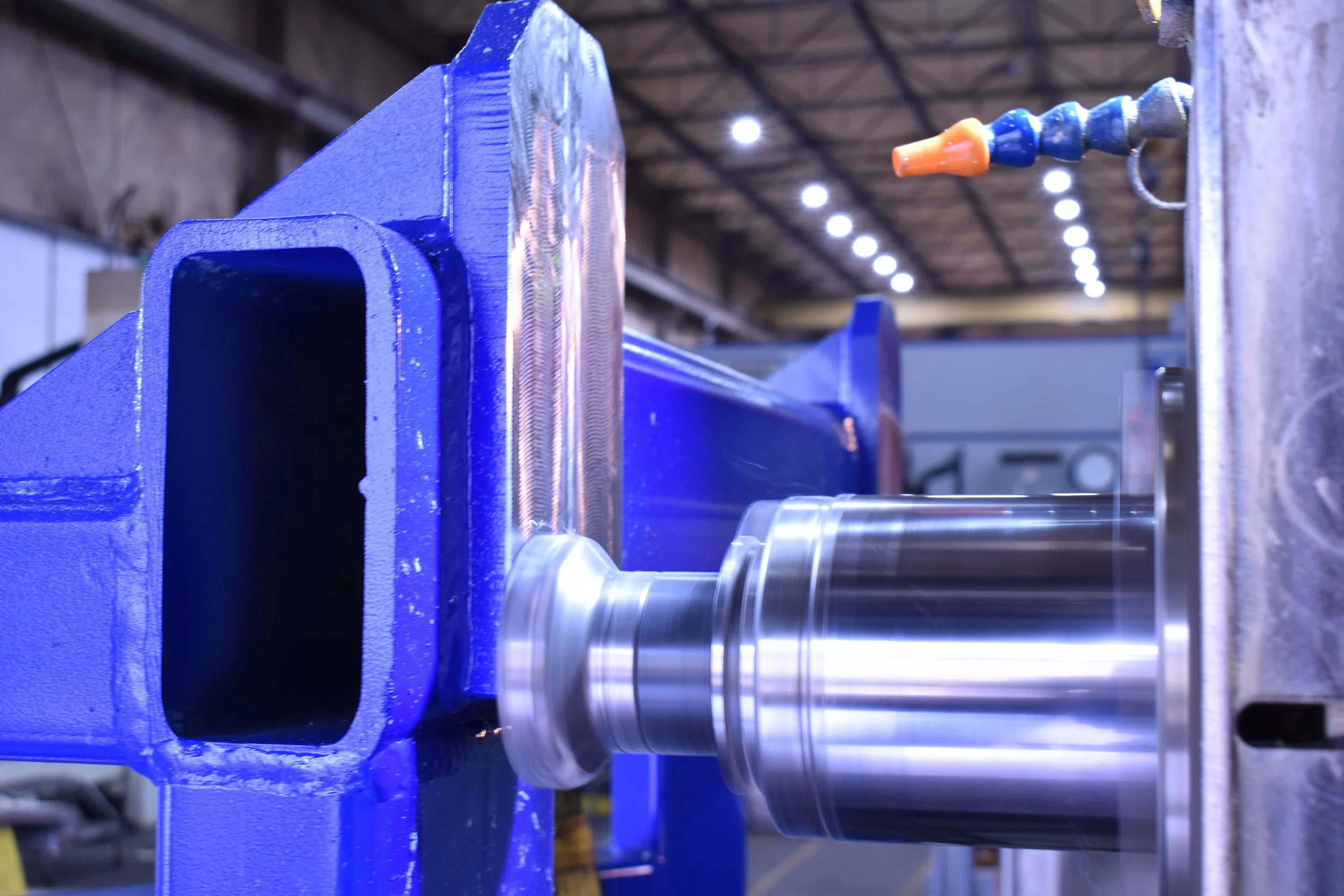

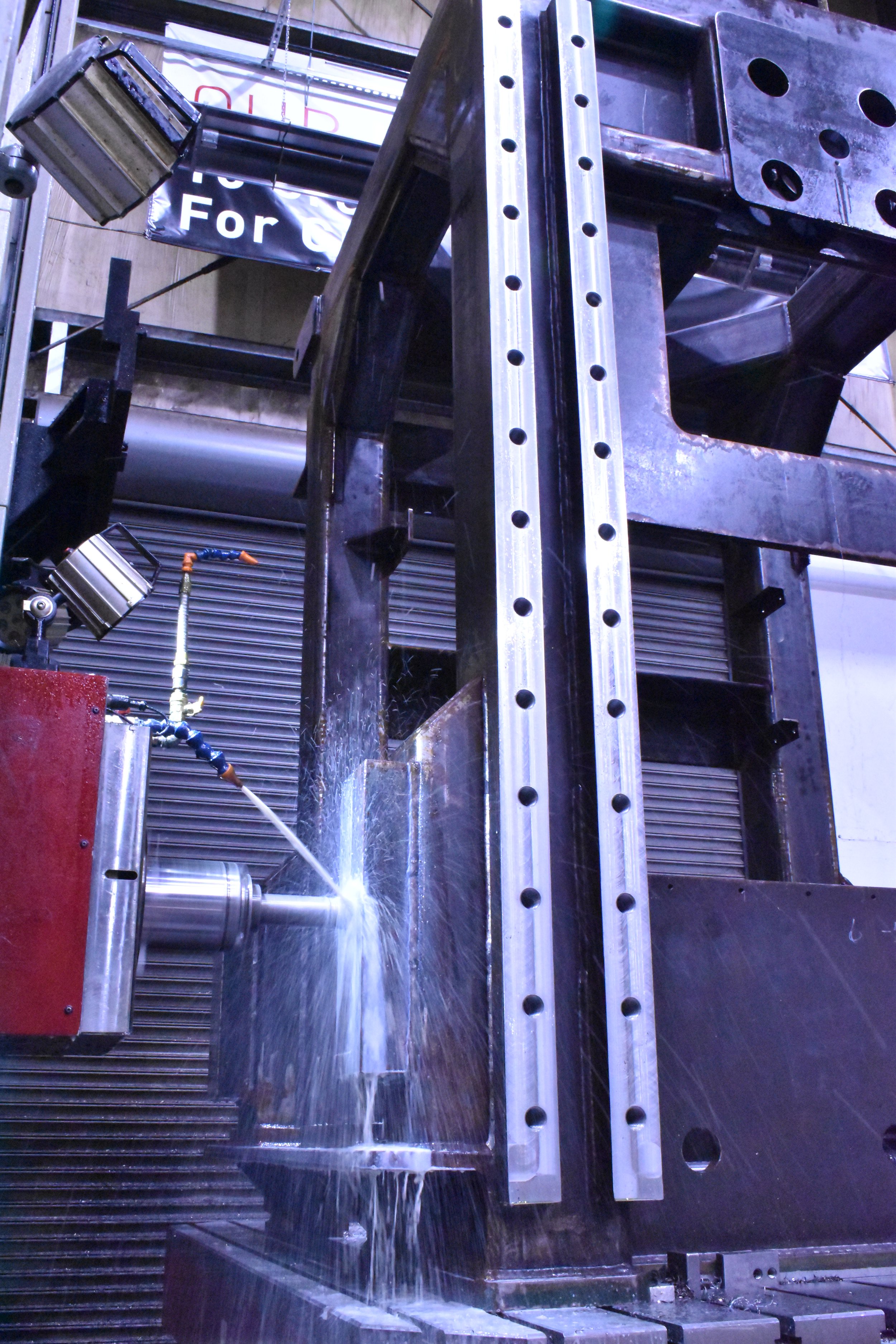

Precision Machining

Our high-torque, large-format CNC milling and turning capabilities enable us to machine complex, high-precision components and massive structures with true aerospace-grade accuracy.

From tight-tolerance vehicle structures and GD&T-critical weldments to challenging hard metals and exotic alloys, we enjoy delivering beautiful parts with consistent geometry, excellent surface finish, and repeatable, reliable quality.

Large-Format Boring & Milling

With extensive experience in alignment-critical builds, we perform precision boring, milling, facing, and geometric correction on oversized frames and large-format assemblies.

These processes ensure correct alignment, perpendicularity, parallelism, coaxiality, flatness, and positional accuracy for sub-systems, machine bases, and heavy mechanical structures.

Assembly & System Integration

Beyond individual components, we excel at building complete mechanical systems. M&F integrates welded structures, machined parts, hydraulics, electrical elements, hardware, and customer-supplied subsystems into fully assembled, ready-to-operate machinery and tooling.

Structural Testing & Proof Loading

We validate safety-critical, failure-intolerant structures through controlled load testing—including proof loads, deflection measurement, NDT, and functional checks. With our in-house test engineering team and large-scale structural test infrastructure, we ensure full mechanical compliance with OEM requirements and deliver fully validated, plug-and-play systems ready for immediate production use.

Project Execution

M&F oversees the full project lifecycle—from engineering and procurement through fabrication, machining, assembly, testing, finishing, and logistics. Our integrated approach shortens lead times, eliminates coordination gaps, and ensures large, complex systems are delivered quickly, accurately, and ready for service. We aim to delight our customers with a smooth, no-headache project experience from start to finish.

Engineering & Design Integration

M&F’s engineering team collaborates with customers to turn concepts and specifications into practical, build-ready solutions. While our center of gravity remains build-to-print manufacturing, our expanding engineering capability enables us to support build-to-spec projects within our areas of deep structural and mechanical expertise. We provide structural analysis, manufacturability guidance, detailed CAD modeling, and design-for-fabrication insight to reduce risk, streamline execution, and accelerate delivery.